Location

Long before many of his colleagues, John Vrieze saw the need for a carbon neutral dairy operation. The founder and owner of Emerald Dairy in St. Croix County, Vrieze owns 2,600 cows across three dairies: Baldwin, Emerald, and Emerald II.

Innovative Renewable Energy Through Public-Private Partnership

In 2004, Vrieze began planning for a digester to spur the greening of his farms. Digesters often require sticker-shocking capital investment. The price tag for Emerald was no exception: $3 million for the digester and its supporting technology. Vrieze patched together funding from the Wisconsin Department of Commerce, the University of Minnesota, investors, bank loans, and his own pocketbook. The Twin Cities company GHD Inc. assembled the digester, which was designed to produce 160,000 cubic feet of methane gas over a 21-day digestion cycle.

Today Vrieze’s digester provides gas for his farms and for 875 homes in the nearby village of Baldwin. Project developer Agri-Waste Inc. partnered with Northern Natural Gas to transfer excess gas via Northern’s Pipeline System for delivery and sale to the manufacturing company 3M to supplement its green energy portfolio.

Whole Farm Strategies

But biogas is not the only byproduct of digestion. Vrieze quickly realized the many potential uses for the digester wastewater. Used as fertilizer for the farm, the wastewater helped Vrieze reduce his fertilizer purchase by 95 percent. He added phosphorus-capture technology, which limited the potential for harmful runoff into nearby streams, and also produced fertilizer pellets that he could sell. With every improvement, the water became a little cleaner, and eventually Vrieze was able to eliminate his now obsolete manure lagoons. His treated wastewater was clean enough to discharge directly into nearby Dry Run Creek.

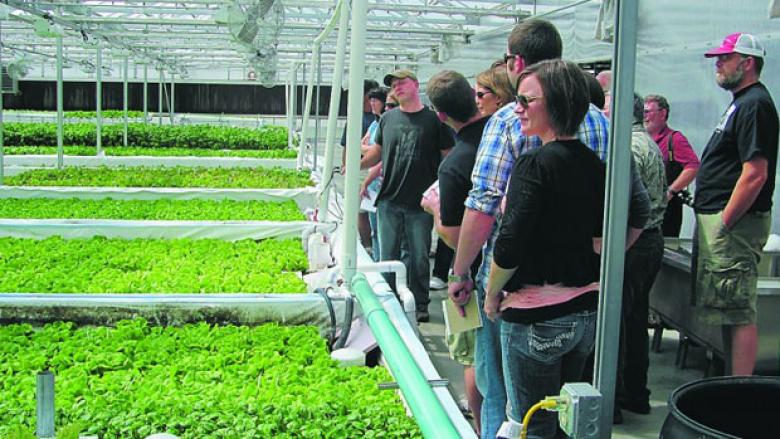

But Vrieze wasn’t done; he installed another digester at his 1,050-cow Baldwin Dairy. Here the wastewater was used to feed Future Farm, a high-tech greenhouse and fish farm cofounded by Vrieze and Steve Meyer. Gas and heat from the digester provide the energy. The wastewater flows first to the fish farm, nurturing thousands of tilapia. Then the aquaponics greenhouse uses the tilapia water to grow lettuce and herbs, cleaning the water at the same time.

It’s a lot of moving parts, and economic returns are not yet complete. But, after some down and neutral years, profit is on the rise. Vrieze, Meyer, Emerald Dairy, and Future Farm are breaking trail towards sustainable, closed-loop food systems that will help green Wisconsin’s dairy industry.

Emerald’s scale of production allows for million dollar investments in efficient, high-capacity biogas systems of which there are only 30 in the whole state. However, biogas has a bright future in the dairy industry. As desire for reliable, homegrown, renewable energy grows, Wisconsin’s dairy industry has the potential to fill a growing and increasingly profitable niche.